Sandblasting, Coatings & Metal Fabrication for Demanding Projects

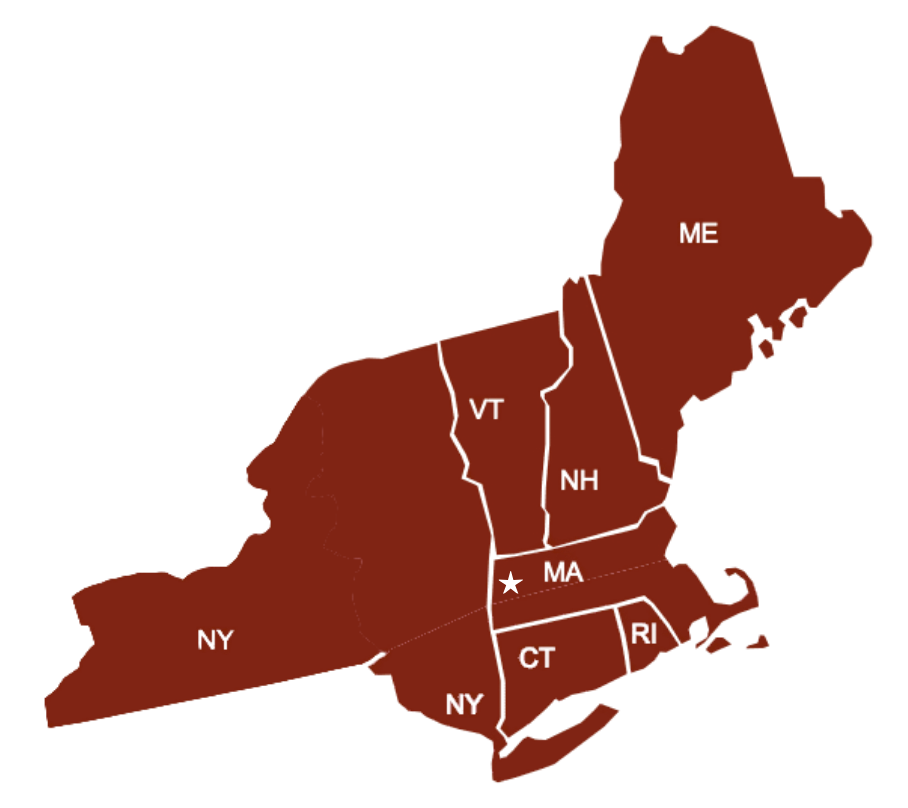

Supporting Commercial, Industrial & High-End Residential Projects Across New England & New York

ABRASIVE BLASTING

- Media Blasting

- Steel Grit Blasting

- Sand Blasting

- Coating & Corrosion Blasting

- Preparation Blasting

- Precision Blasting

- Fleet vehicle Correction & Refurbishment

- Welding & Metal Repair as Needed

- Recoating and corrosion protection

- Undercoating & Wax Protection

- Highway and Heavy-use Fleet Vehicles

FLEET REFINISHING

WHAT WE DO

- Structural & Plate Fabrication

- Steel & Aluminum Fabrication

- Custom & Luxury Metalwork

- Component & Assembly Fabrication

- Repair, Modification & Refurbishment

- Specialty & Outdoor Fabrication

- Exposed Structural Steel Fabrication

- Canopies, Sunshades, & Entry Features

METAL FABRICATION

- Epoxy Coatings

- Urethane / Polyurethane Coatings

- Zinc-rich Coatings

- Alkyd and Maintenance Coatings

- Specialty Protective Coatings

- Undercoating & Wax Corrosion Protection

- & More depending on Project Needs

INDUSTRIAL COATINGS

WHO WE ARE

Founded in 1999, East Coast Refinishing began as an Abrasive Blasting and refinishing operation and has grown into a diversified contractor supporting Steel, Coating, and Fleet Refinishing work at scale. Over time, our capabilities expanded to include Metal Fabrication, Industrial Coatings, and Custom Metalwork such as railings and architectural elements. Today, our operations are supported by a 32,000ft² facility out of Pittsfield, MA built to handle high-volume and oversized work, allowing us to take on more complex projects while maintaining a consistent standard of quality. That growth has been driven by a focus on workmanship, reliability, and long-term performance.

32,000 ft²

FACILITY

1999

FOUNDED

500+

PROJECTS

WHO WE SERVE

Fabrication & Steel Supply

Industrial & Manufacturing

Commercial & Residential Construction

Municipals & Government

Engineering & Architecture

Infrastructure & Utilities

HOW WE WORK

- Review the scope and requirements first

- Plan the work around schedule and access

- Prep and execute to match service conditions

- Review for quality before we schedule pickup or drop off

OUR PROCESS

1

Define the scope and requirements

Requirements, constraints, and expectations are reviewed to establish a clear path forward.

2

Prepare and Process

Materials or assets are prepared, corrected, or processed in-house based on project needs.

3

Apply Finishing or Protection

Finishing, coating, or protection is applied based on intended use and service conditions.

4

Review for Readiness

Completed work is checked to confirm quality and readiness for pickup or drop off.

WHAT WE DO

Abrasive Blasting

Metal Fabrication

Industrial Coating

Fleet Refinishing

PROUDLY SERVING NEW ENGLAND & NEW YORK SINCE 1999

testimonialS

"Claudia and the guys at East Coast Refinishing are great to do business with. Quality work 100% of the time. I have been doing business with them for years. If you need a spray in bedliner go see these guys, better quality and durability than factory spray in bedliners."

DAVE K.

Our Certifications & Partnerships

Claudia and the guys at East Coast Refinishing are great to do business with. Quality work 100% of the time. I have been doing business with them for years. If you need a spray in bedliner go see these guys, better quality and durability than factory spray in bedliners.

-Dave K.

See what our clients are saying